AODD PUMPS

SEMI SERIES

semiconductor, pharmaceutiical, ultra high purity

MAIN FEATURES

The pumps from SEMI series have been designed especially for the purpose of semiconductor industry. The whole assembly process of these unique products is completed in a class ISO 5 (according to norm ISO 14644-1), involving a double cleaning of the parts, their testing with de-ionized water, and finally sealing in plastic foils.

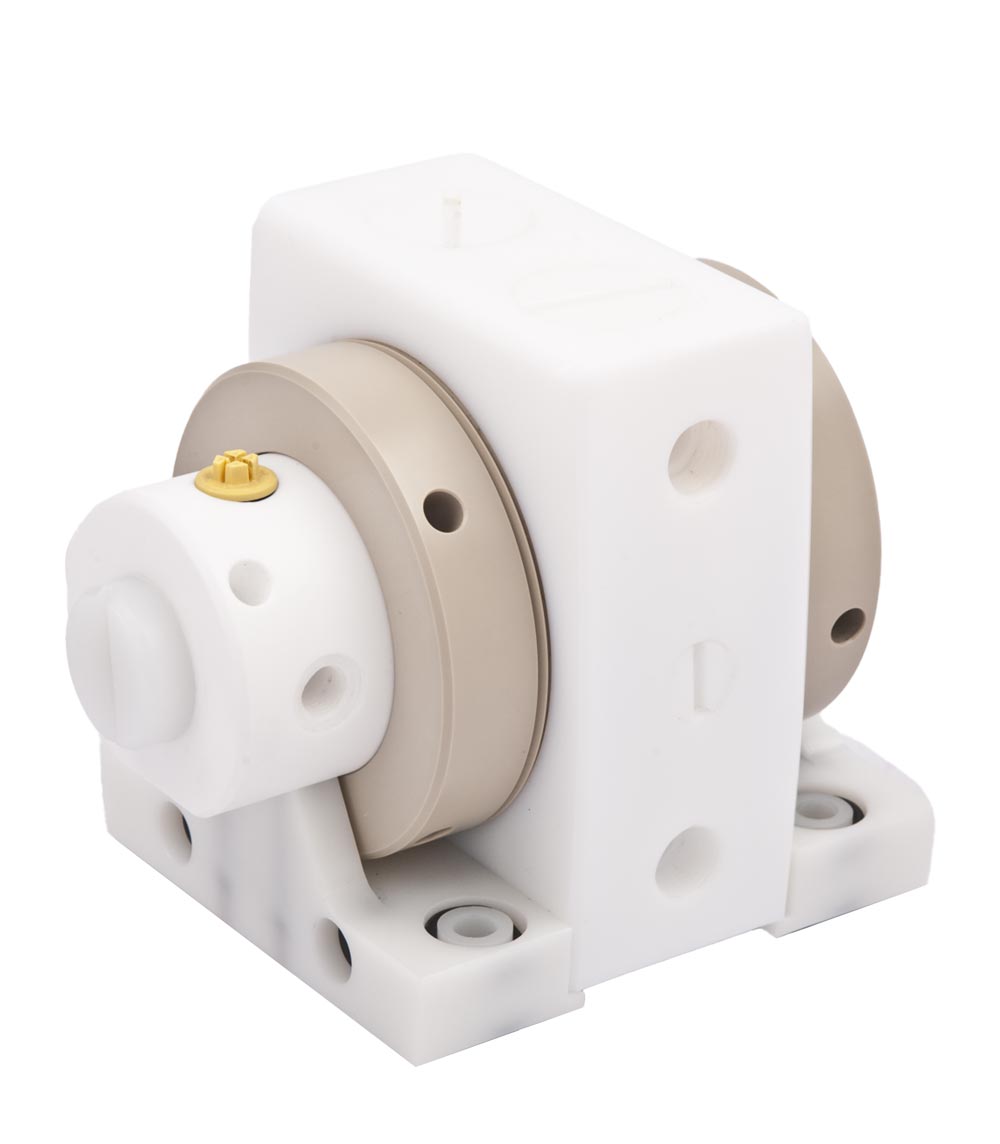

All parts of the SEMI T and SEMI Hpumps coming in touch with liquids are made of PTFE (polytetrafluoroethylene).

The housing parts of the SEMI E pump coming in contact with liquids are made of UPPE (ultra pure polyethylene).

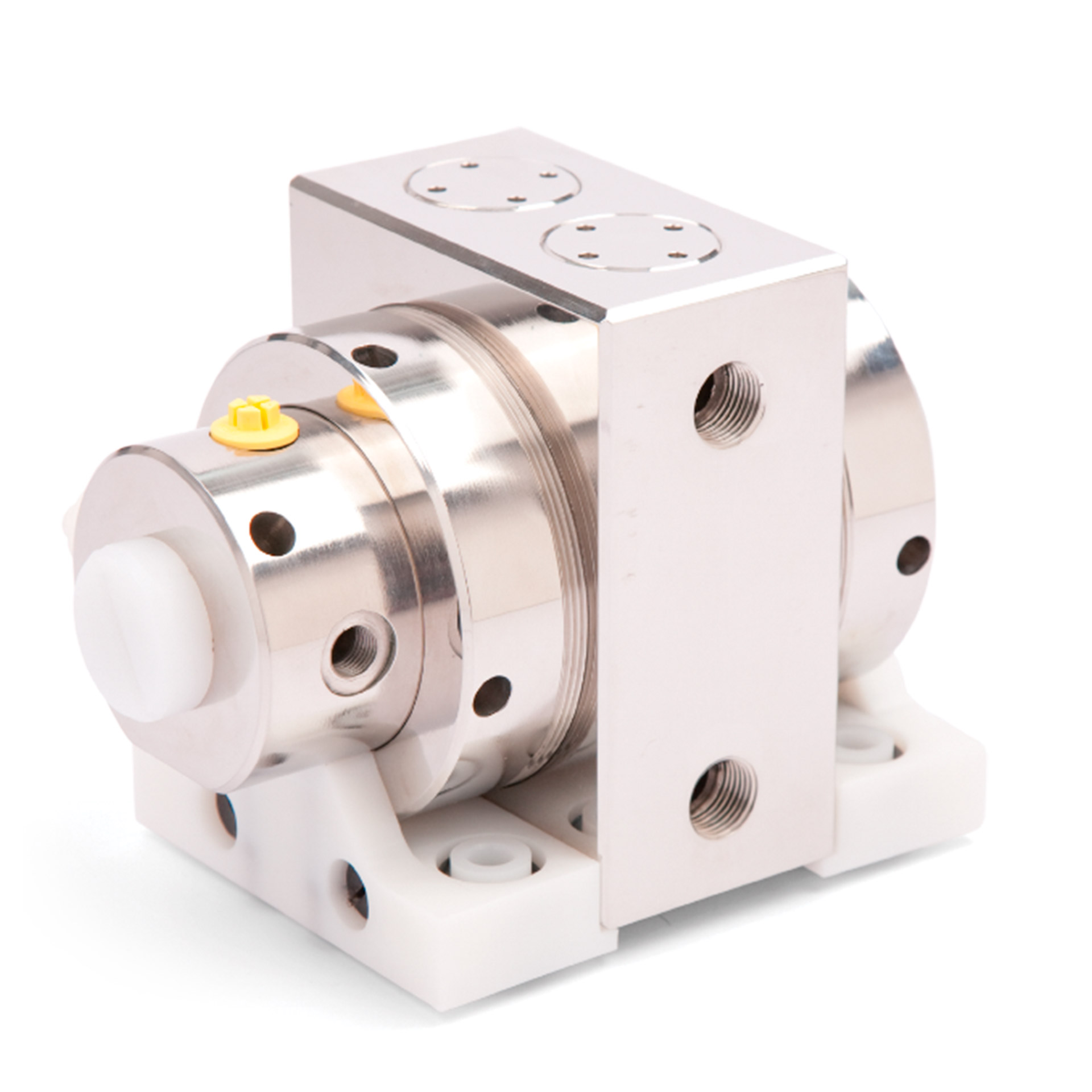

The housing parts of SEMI S pump coming in contact with liquid are made of AISI 316L stainless steel.

360 VIEW

FEATURES

- no metal parts (even down to atomic scale)

- no elastomer o-ring seals

- no lubrication in air valve

- Class 100 Clean-Room assembly, tested with de-ionised water and double sealed package

- TFM diaphragms, robust and dependable

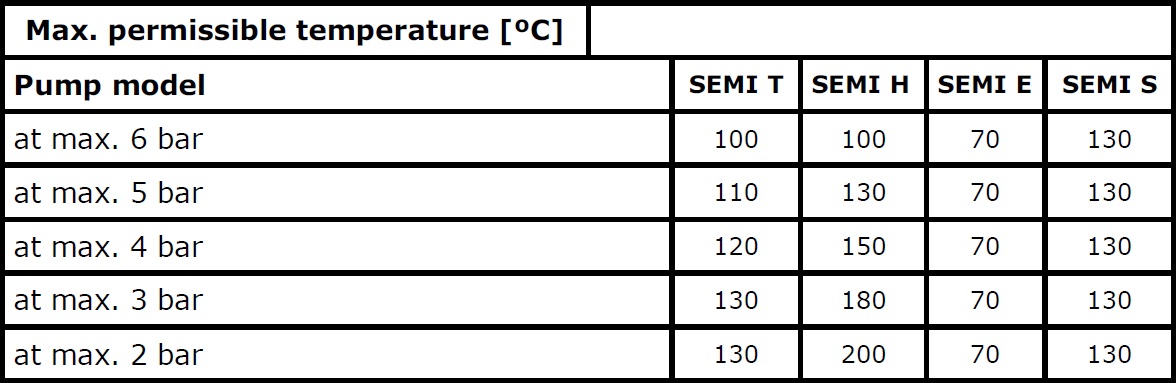

- 4 materials for diffrent applications with max. temperature 200°C

- machined form solid material an advanced CNC Machining and Turning Centre

- pulsation dampeners, leak detection, electronic/pneumatic controls and monitoring available for all sizes

- easy ‘preventive maintenance planning’ (PMP) with just 40% of spare parts compared competitor

- Capacities from 10–100 l/min

- 4 sizes made from PTFE/UPPE (ultra pure polyethylene) for acids and caustics, with no metal parts even down to atomic level and temperature range up to +130 degrees Celsius (SEMI T series)

- 2 sizes made from PTFE for applications with acids and caustics up to +200 degrees Celsius (SEMI H series)

- 4 sizes of UPPE for slurries (SEMI E series)

- 2 sizes centre housing of stainless steel for solvents (SEMI S series)

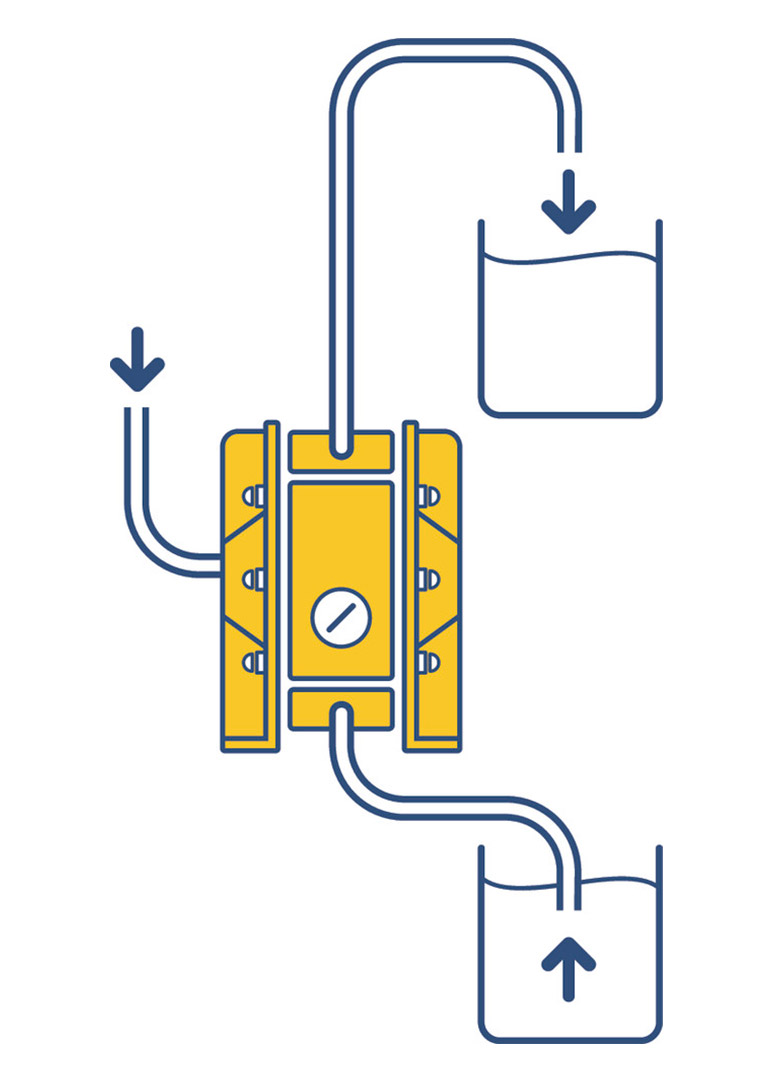

HOW TO INSTALL DELLMECO PUMPS?

Self-Priming Application

The suction lift rangemis up to 8 meters. This will vary according to construction materials and application parameters. All data are based upon pumping water at 20°C

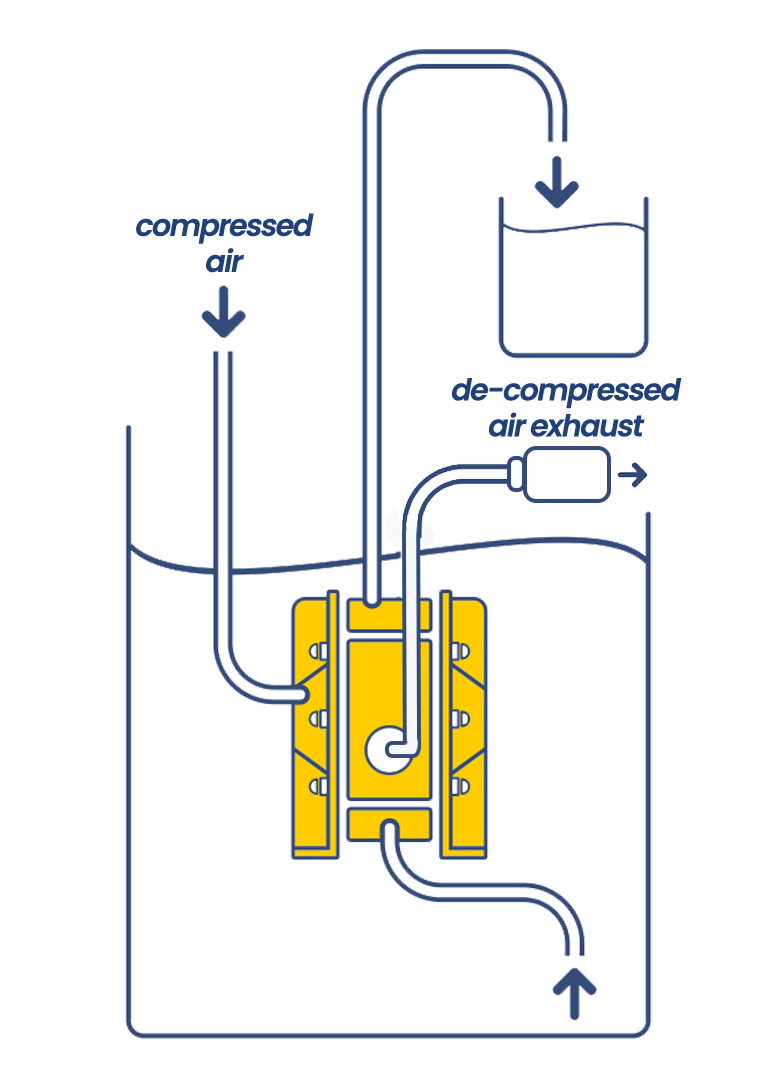

SUBMERGED OPERATION

Our pumps can operate under full submersion. The construction materials must be suitable for the surrounding liquid and the outlet must be positioned above the liquid level.

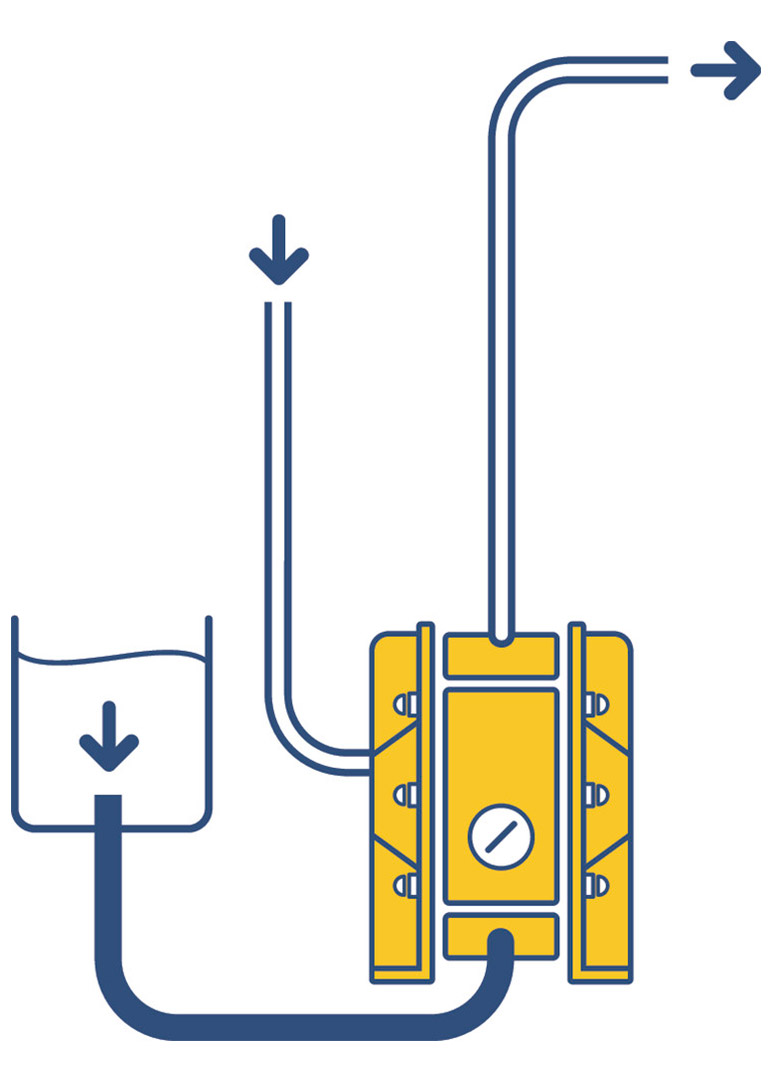

POSITIVE SUCTION HEAD

As a method for completely emptying holding tanks, clarifiers or similar containers. Optimum inlet pressure should be kept at 0.2-0.3 bar.

SEMI PUMPS SUMMARY

Model: SEMI T

Materials: center housing TFM/PTFE; side housing UPPE

Pump sizes: 10, 20, 50

Products: acids and caustics

Materials: center housing UPPE; side housing UPPE

Pump sizes: 10, 20, 50

Products: slurries

Materials: center housing UPPE; side housing PTFE

Pump sizes: 10, 20

Products: hot applications with acids and caustics

Materials: center housing SS 316L; side housing PTFE cond.

Pump sizes: 20, 50

Products: solvents

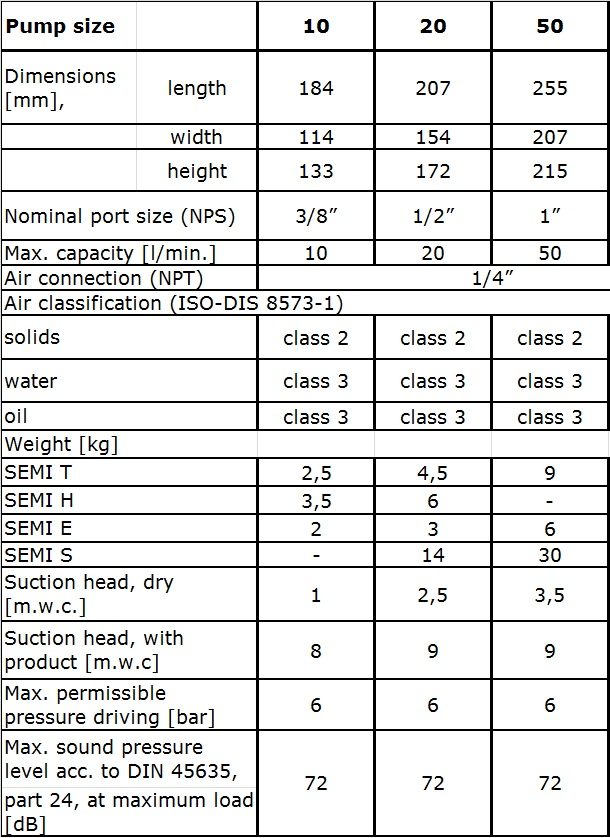

SEMI TECHNICAL DATA

SEMI ADDITIONAL EQUIPMENT

Pneumatic stroke counting system (code SC5, SC6)

The strokes of the pump will be automatically counted after introducing the codes SC5 and SC6. The pressure change in the air chamber behind one of the diaphragms will be noted by the pressure switch. To function well, the counting system must be fed with the pressure of at least 1.5 bar.

The two types of the counting system are:

– SC5 – pressure switch 1 – 10 bar, cpl. assembled with socket with

cable 5 m; adapter straight NPT ¼”; hose DN 4/6, 2.5 m

– SC6 – as SC5 and a stroke counter.

Diaphragm sensor (code DM1, DM3, DM4)

The role of the diaphragm sensor is to detect a diaphragm fracture. It is installed in the muffler and is designed to be able to operate for any liquid. There are three types of diaphragm sensors:

DM1: 2-wire-Namur, intrinsically safe EEx ia IIC T6

DM3: 3-wire

DM4: 3-wire with plug (only for pumps sizes 10, 20, 50)

Flaretek© – connectors for PFA pipe (code CF)

Flaretek©-connectors can be used with the SEMI T and SEMI H pumps in their suction and discharge ports.