AODD PUMPS

Polyethylene & PTFE

chemicals, food and beverage, electro-plating, paper manufacturing

MAIN FEATURES

DELLMECO air operated diaphragm (AODD) pumps are suitable for a wide range of applications.

They have a high abrasive resistance and withstand aggressive chemicals including acids, oils, solvents, paints, sludges and even media containing solid particles such as found in waste water. These pumps can also be used for transferring powders.

All the pumps are self-priming and the capacities and pressure can be easily controlled.

This pump is a positive-displacement pump that transfers fluids by means of diaphragms movement operated by compressed air.

The casing in contact with the fluid is made of PE (polyethylene), PE conductive, PTFE (polytetrafluoroethylene), PTFE conductive.

Designed to succeed

– temperatures up to + 120°C

– pressure up to 14 bar

– lubrication-free operation

– low air consumption

– abrasion resistance (PE, PE conductive)

Flexible installation

– BSP as standard

– PN10, PN16, ANSI, NPT, JIS, RJT, split manifold configurations available

– connections may rotate 180°

Solid, compact and strong

– housing machined from solid PE, PTFE as well as conductive PE and PTFE

– withstands aggressive chemicals

– gentle pumping action

– viscous media transfer

Perfect diaphgram

– completely smooth liquid-side surface (no holes)

– no metal in contact with the media

– materials made to match the application

360 VIEW

HOW TO INSTALL DELLMECO PUMPS?

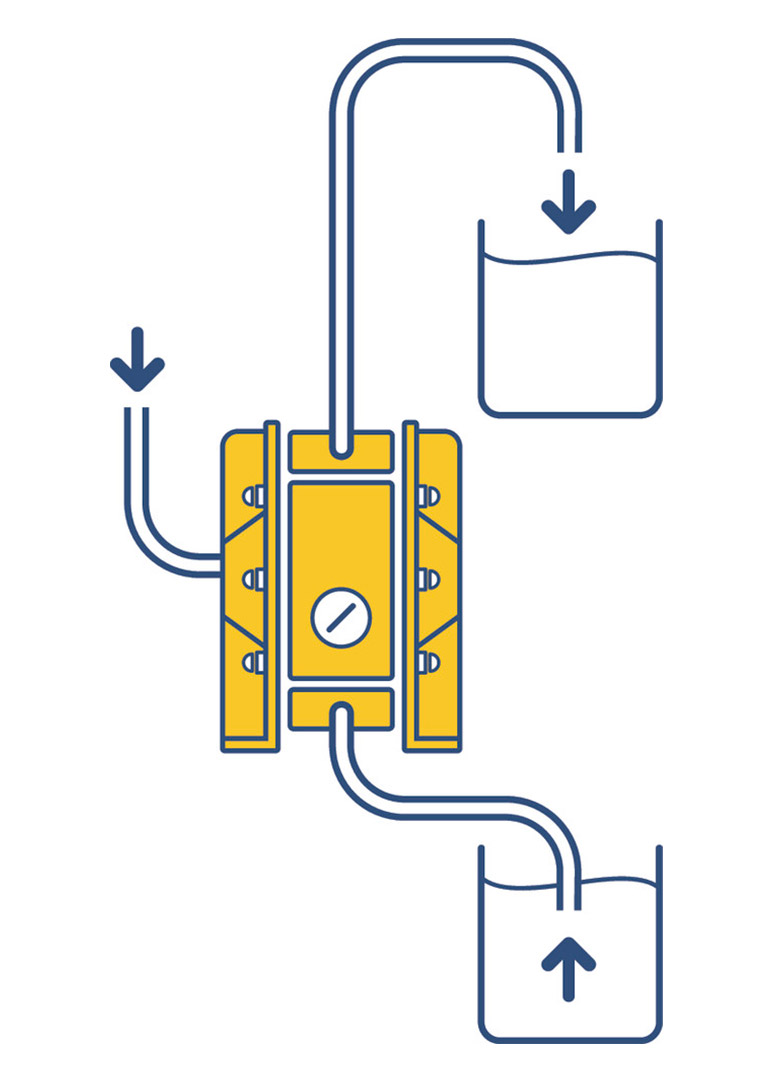

Self-Priming Application

The suction lift rangemis up to 8 meters. This will vary according to construction materials and application parameters. All data are based upon pumping water at 20°C

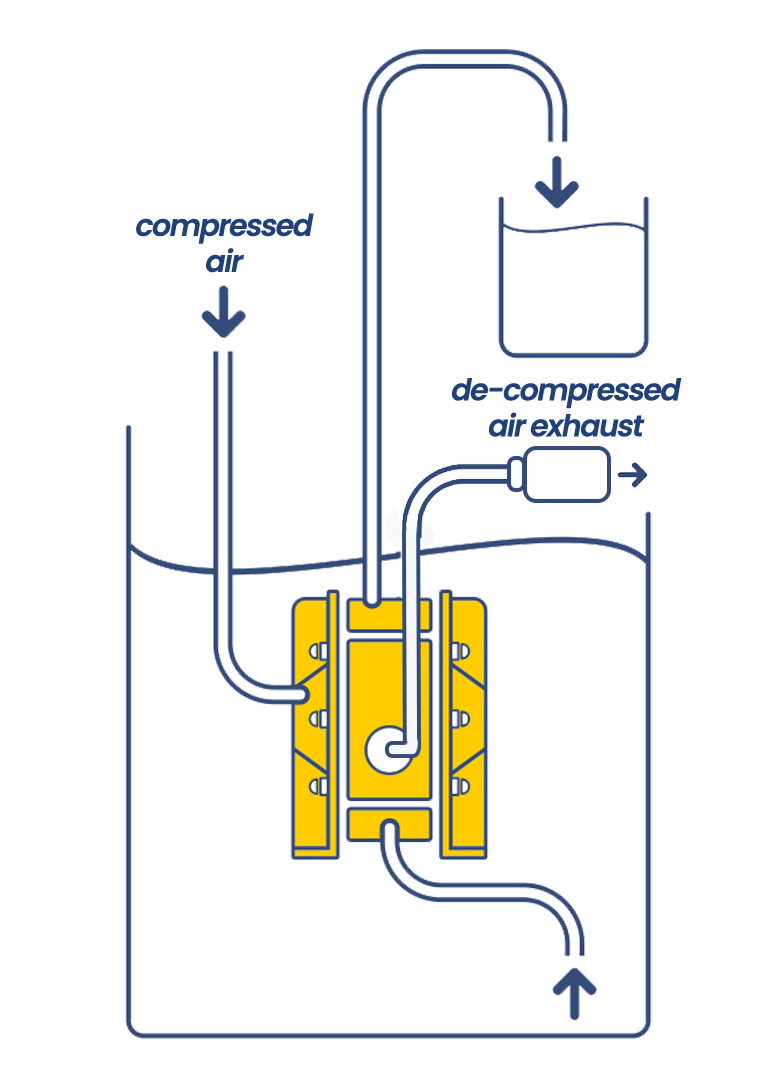

SUBMERGED OPERATION

Our pumps can operate under full submersion. The construction materials must be suitable for the surrounding liquid and the outlet must be positioned above the liquid level.

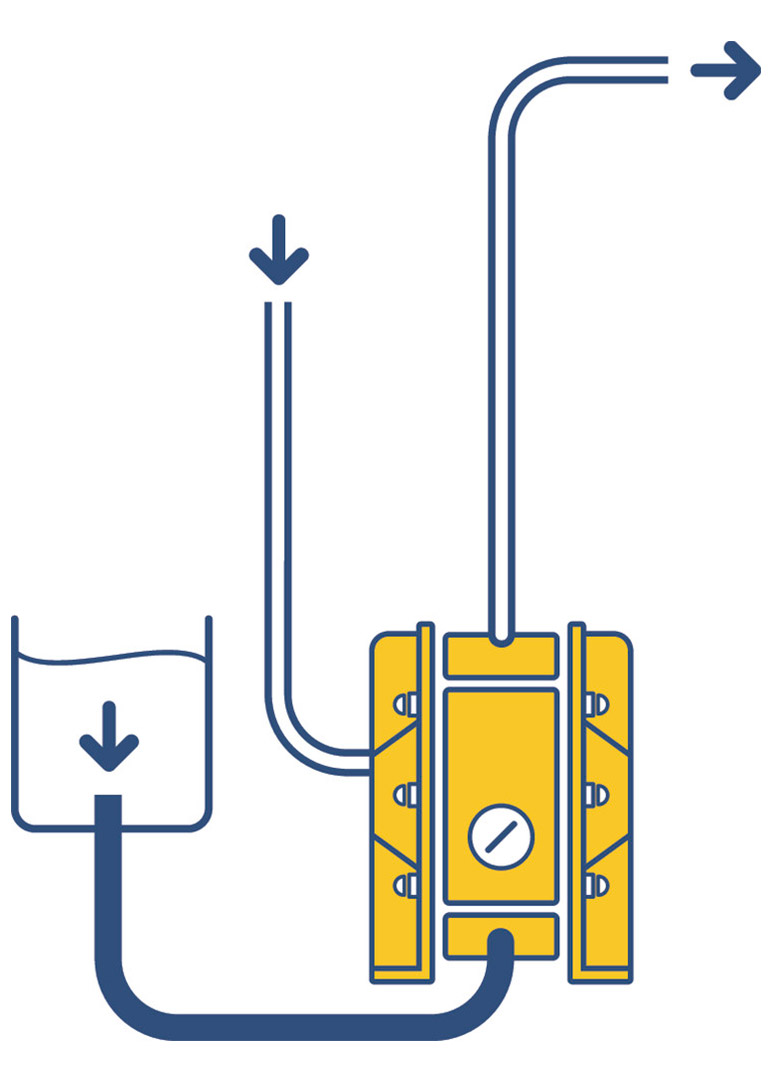

POSITIVE SUCTION HEAD

As a method for completely emptying holding tanks, clarifiers or similar containers. Optimum inlet pressure should be kept at 0.2-0.3 bar.

RECOMMENDED INSTALLATION GUIDELINES

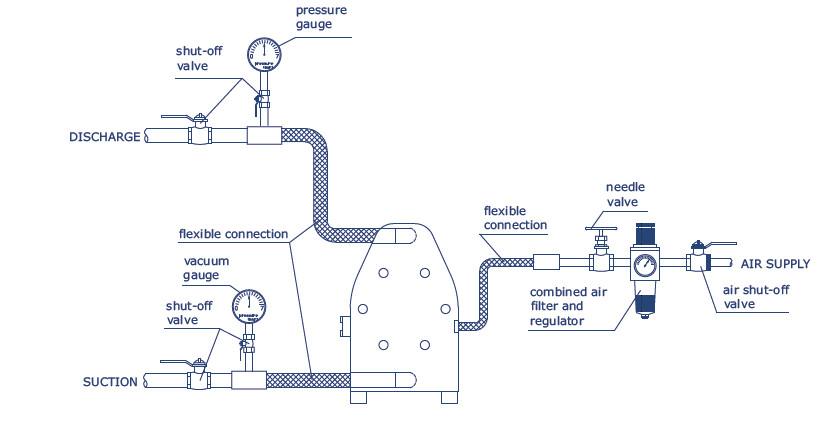

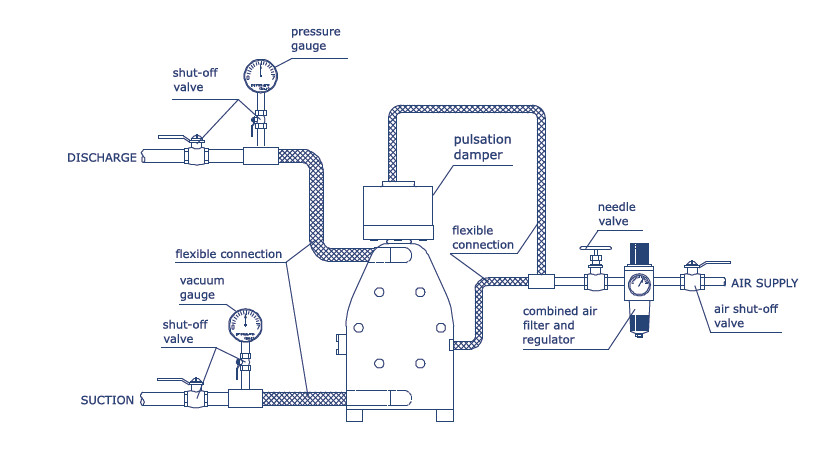

To reduce piping and pump connections stresses, we recommend flexible connections on both the inlet and outlet pipes and air inlet connections.

For best results DELLMECO recommends installing the pulsation dampener on the discharge side of the pump.

Without pulsation dampeners

With pulsation dampeners

CONNECTION TYPES – PLASTIC SERIES

Standard BSP (inner thread)

This is a standard connection for all plastic and metal pumps.

S – split connections

All pump models can be fitted with split connections (code S). The pump can be converted from a standard double-action air-driven diaphragm pump into a unit with two single chambers. The suction and discharge connection are replaced by a split sleeve with a separate suction and discharge for both chambers. Both chambers are independent and by having them with the same drive it means there can be two media streams in a 1:1 ratio.

Flange connections PN10

This options offers the possibility to use flange connectors according to DIN/PN10. The inlet/outlet flange connections are by thread bushings made of stainless steel. The attached O-rings have to be inserted into the grooves of the manifolds to improve sealing before connecting the pump.

F1 – Flange connection PN10 EPDM

F2 – Flange connection PN 10 NBR

F3 – Flange connection PN10 FEP/FPM

Other types of flange connections

F4 – JIS B2220

F7 – PN10 DIN 2576

F8 – ANSI 150 RF SO

F9 – PN10/16 DIN 2277/2278

Other connections on request.

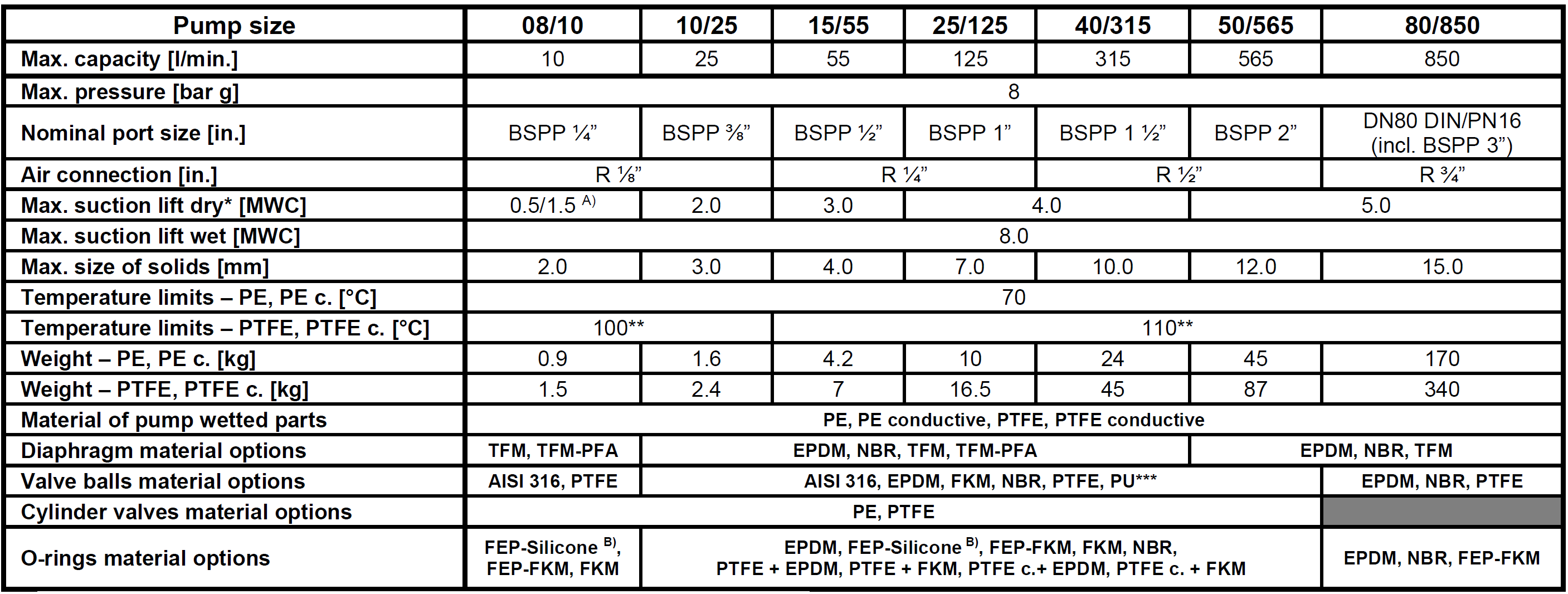

TECHNICAL DATA

Polyethylene and PTFE materials

Where ATEX is required

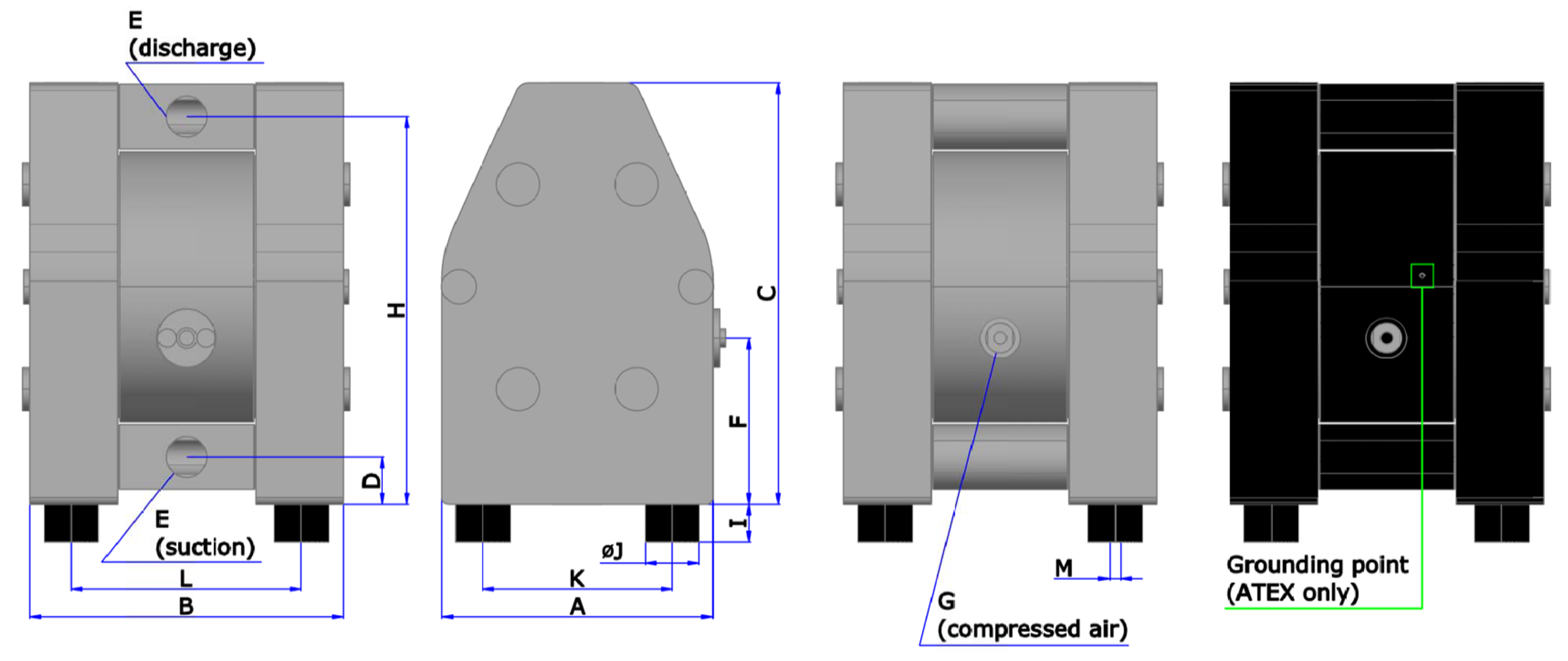

PLASTIC PUMP DIMENSIONS

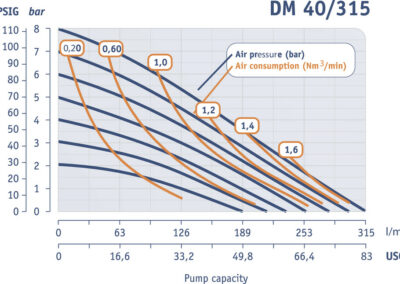

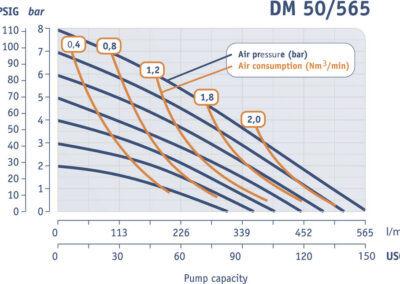

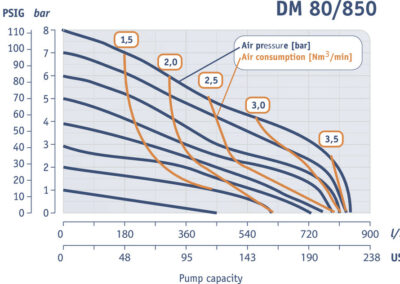

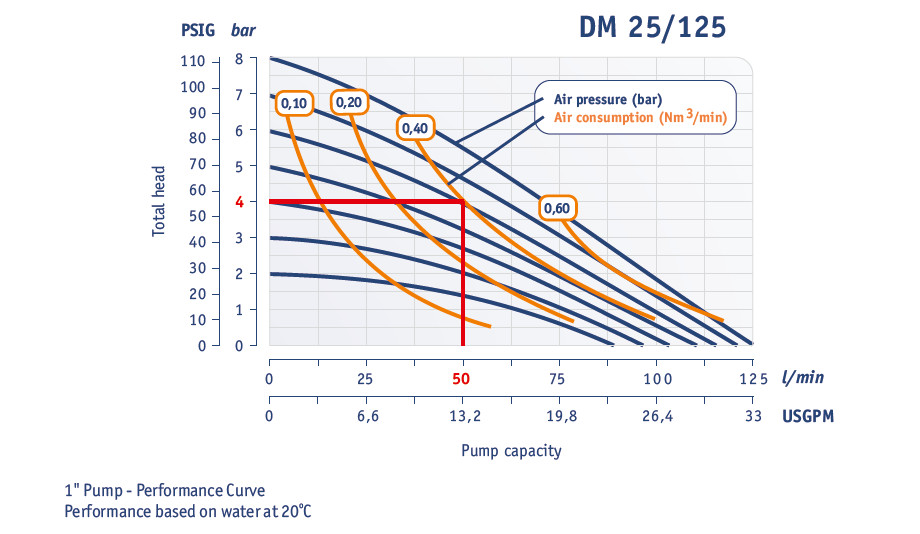

PLASTIC PUMP CAPACITY

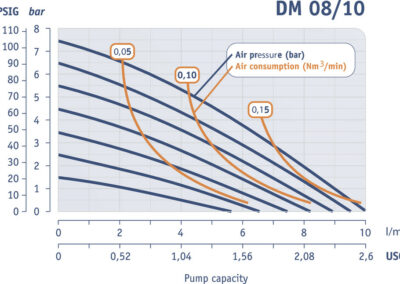

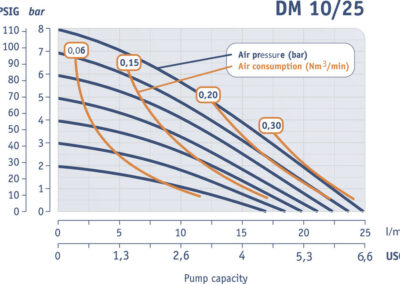

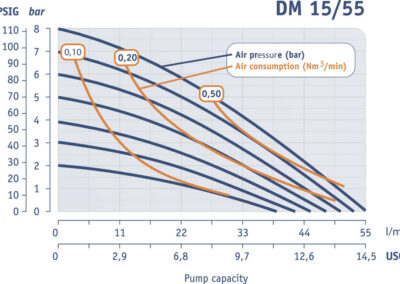

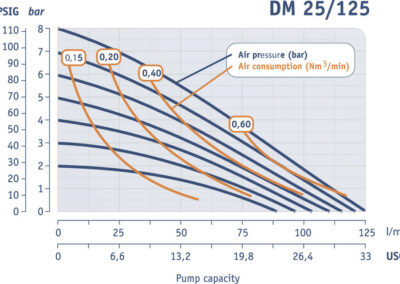

HOW TO SELECT THE PUMP SIZE

1. Enter flow rate and pressure. (example: 50 l/min and 4 bar)

2. Read off the approximate energy requirements in Volume and Pressure. (example: 0.40 Nm3/min at 6 bar)

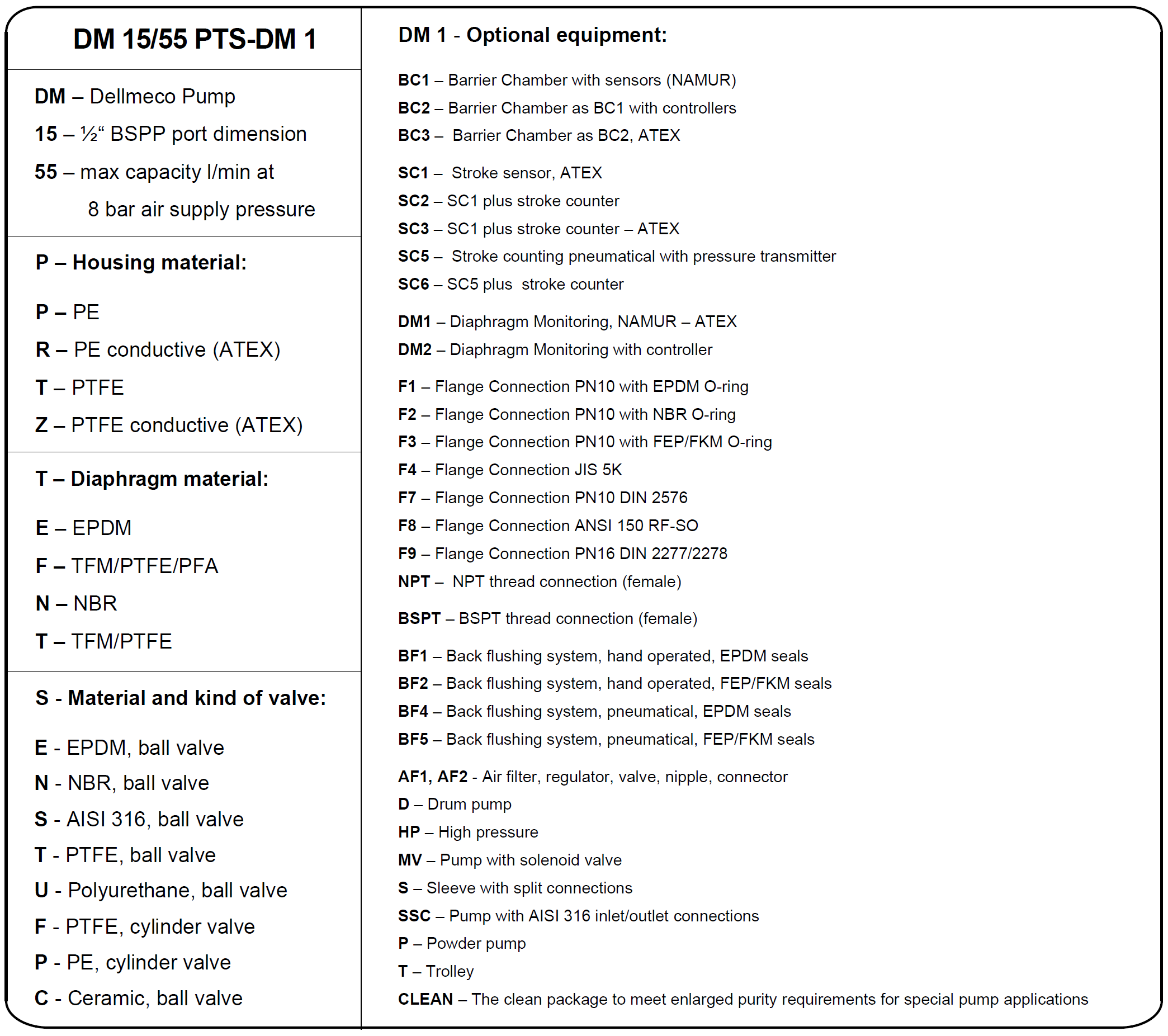

PLASTIC PUMP CODE